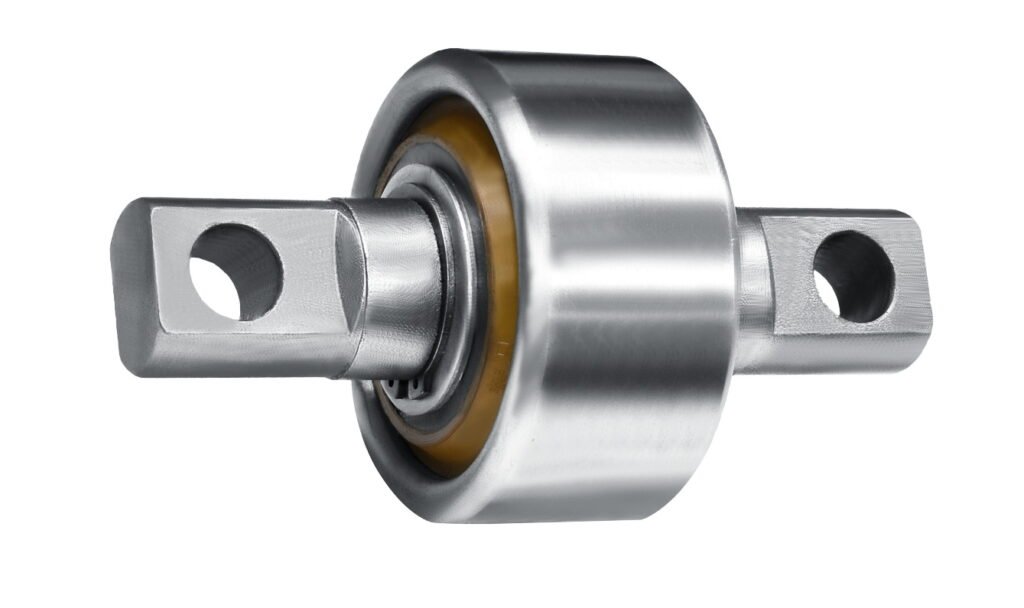

Mitsubishi engine mounting ME-013965

The manufacturing process is where the magic happens. It’s a multi-step journey that starts with material selection and design. We use high-precision molds and state-of-the-art

The manufacturing process is where the magic happens. It’s a multi-step journey that starts with material selection and design. We use high-precision molds and state-of-the-art

Our engine mounting rubber are designed to deliver outstanding performance. They are highly elastic and can withstand varying temperatures without deforming or breaking. This means

Our engine mountings are crafted from top-notch rubber materials. Think of it like this: natural rubber is the workhorse of the bunch. It boasts high

Heavy-Duty Trucks**: These cores are specifically designed for use in heavy-duty trucks, where they play a crucial role in the clutch system.

Premium Materials**: Our heavy-duty truck accessory hangers are crafted from top-notch materials. For instance, some are made from high-quality steel, which is renowned for its

These engine mounting play a crucial role in your vehicle’s engine mounting system. They support the weight of the engine and isolate unbalanced engine disturbance

Assembly Method**:

The components of a torsion rubber bushing are typically assembled through extrusion molding and vulcanization processes to ensure a tight bond between parts.

Functional Features**: Shock absorption and cushioning are achieved through the elastic deformation of the rubber layer, while self-lubricating sleeves and buffer layers reduce friction and wear, extending the service life of the components.

One of the standout features of our engine mountings is their vibration damping ability. Picture this: your engine is running, and it’s generating all sorts

Torque rubber BUSH for heavy-duty trucks are typically made from high-quality synthetic rubber compounds. These materials are engineered to withstand extreme operating conditions, including

hollow torque rod bush built with premium rubber materials and a reinforced hollow core, it absorbs shocks and minimizes vibrations during operation, ensuring smooth axle

In order to further enhance the protective performance of the packaging, we use a multi-layer protection structure, use sturdy wooden boxes and other materials for

Enhancing Durability Fatigue Resistance: Rubber materials have excellent fatigue resistance, maintaining stable performance despite repeated deformation and recovery cycles. This allows the torsion rubber core

Vibration Reduction** Heavy-duty trucks generate significant vibrations due to their powerful engines and the weight of their loads. Torque rubber cores act as shock absorbers,

The primary function of a torque rubber core is to provide a flexible and resilient connection within the clutch system. It helps to

Enhanced Safety** By reducing vibrations and maintaining axle stability, torque rubber bush contribute to safer driving conditions. Stability is especially critical for trucks navigating mountainous

QUANZHOU SINOR SUPPLY IN TORQUE ROD BUSH, V STAY, CONTROL BALL JOINT, AUTO BUSHING RUBBER BUSHING,CENTRAL BEARING SET, ENGINE MOUNTING, REPAIR KITS ETC. OURPRODUCTS ARE SUTTABLE FOR MERCEDES,VOLVO,SCANIA,MAN,HOWO,HYUNDAL,ISUZU,NISSAN,MITSUBISH,FAW SIE.DELONG,AUMEN DAFC AND OTHER BRANDS OF HEAVY TRUCKS.

Natural rubber is a widely used material in heavy-duty applications because of its excellent elasticity, flexibility, and resilience. Torque cores made from natural rubber are effective in absorbing vibrations and handling a wide range of temperatures, making them ideal for general applications where durability and flexibility are required.

Polyurethane is a highly durable and resilient material that offers excellent load-bearing capacity and impact resistance. PU torque cores are commonly used in extreme heavy-duty applications, as they provide long-lasting durability and support.

Neoprene rubber is valued for its resistance to oil, heat, and weathering, making it suitable for heavy-duty trucks that frequently encounter harsh environments. Torque cores made from neoprene can withstand higher temperatures and exposure to oils and chemicals without compromising on performance.

– **Advantages:** High resistance to oils, chemicals, and weathering; moderate heat resistance.

– **Applications:** Ideal for trucks operating in oil-rich environments, such as construction and industrial settings.

Superior Vibration Absorption for Smooth Performance Our torque rubber cores are engineered to effectively absorb shocks and reduce vibrations, providing a smoother driving experience even in rugged conditions. This enhances driver comfort while protecting other vehicle components from wear.

Crafted from high-quality, durable rubber materials—such as natural rubber, neoprene, and polyurethane—our torque cores are built to withstand extreme temperatures, oils, and harsh environments, ensuring a long-lasting performance that saves on replacement costs.

Designed specifically for heavy-duty trucks, our torque cores offer exceptional load-bearing capabilities. This ensures that they perform reliably under the intense pressure of high loads, making them suitable for demanding applications like construction, mining, and long-haul transportation.

With customization options available, we offer torque rubber cores tailored to your exact specifications, including material, size, and design. This ensures compatibility with various truck models and optimizes performance for specific operating environments.

Or contact us to see our certificates

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

Please fill the from to contact us and we’ll get back to you right away!