BENZ Engine Shocking Abosorb Rubber Engine Mounting 6452400118

Our engine mounting are engineered to provide a perfect seal, preventing leaks of oil, coolant, and combustion gases. This not only enhances the performance of

Our engine mounting are engineered to provide a perfect seal, preventing leaks of oil, coolant, and combustion gases. This not only enhances the performance of

Whether based on client-provided drawings or samples, our R&D team quickly and effectively responds to each request. Continuously innovating with the latest material science and

We take great care in packaging our rubber buffers to ensure they arrive in perfect condition. They are typically packed in woven bags, cartons, or

The material of a center bearing set significantly impacts its performance, durability, and longevity. Common materials include:

Engine mounts are designed to provide stability and reduce the transmission of vibrations from the engine to the vehicle’s frame. This not only enhances the

Reducing Vibration**: The rubber layer cushions vibrations between mechanical components, minimizing noise and wear caused by vibration. This damping effect is especially crucial for the

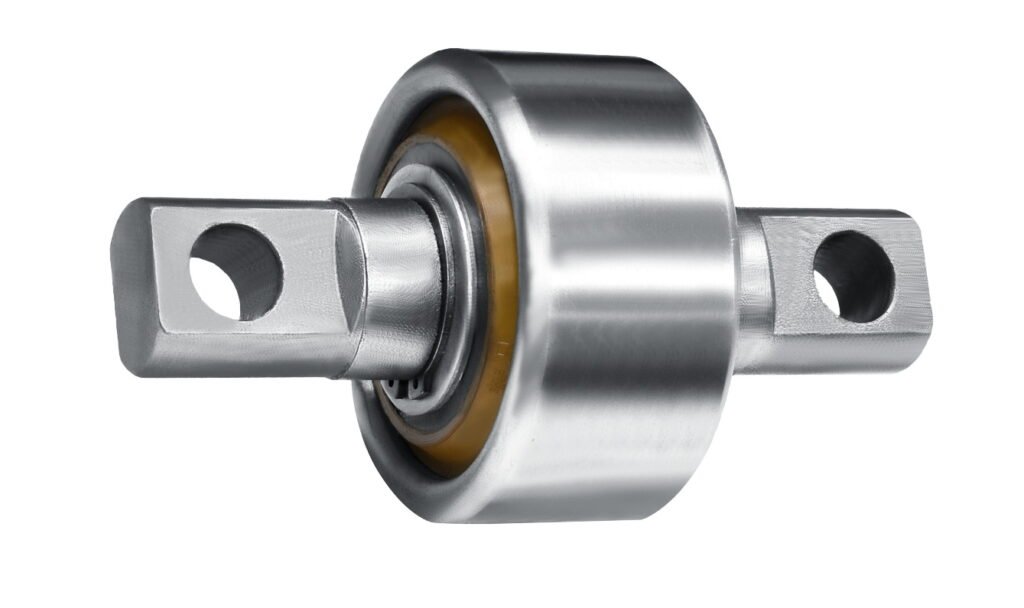

BENZ Thrust Rod Assy Manufacture Rubber Torque Rod bush Material: Top 100% nature rubber and Ingredients are from European. Temperature Resistance: Our Material supports as

Absorbing Impact Forces: When a vehicle moves over uneven surfaces such as bumps and potholes, impact forces are generated. The rubber layer, through its elastic

When you choose our Mercedes torque rod bushings, you’re investing in reliability that keeps your fleet moving. Our bushings are tested to exceed OEM

Our Mercedes torque rod bushings are precision-manufactured to meet the exact specifications of Actros, Axor, and Arocs heavy-duty truck models. Constructed with high-quality, oil-resistant

Manufactured to Mercedes OEM specs, perfect fit for Actros, Axor, Atego & other heavy-duty trucks.

QUANZHOU SINOR SUPPLY IN TORQUE ROD BUSH, V STAY, CONTROL BALL JOINT, AUTO BUSHING RUBBER BUSHING,CENTRAL BEARING SET, ENGINE MOUNTING, REPAIR KITS ETC. OURPRODUCTS ARE SUTTABLE FOR MERCEDES,VOLVO,SCANIA,MAN,HOWO,HYUNDAL,ISUZU,NISSAN,MITSUBISH,FAW SIE.DELONG,AUMEN DAFC AND OTHER BRANDS OF HEAVY TRUCKS.

Natural rubber is a widely used material in heavy-duty applications because of its excellent elasticity, flexibility, and resilience. Torque cores made from natural rubber are effective in absorbing vibrations and handling a wide range of temperatures, making them ideal for general applications where durability and flexibility are required.

Polyurethane is a highly durable and resilient material that offers excellent load-bearing capacity and impact resistance. PU torque cores are commonly used in extreme heavy-duty applications, as they provide long-lasting durability and support.

Neoprene rubber is valued for its resistance to oil, heat, and weathering, making it suitable for heavy-duty trucks that frequently encounter harsh environments. Torque cores made from neoprene can withstand higher temperatures and exposure to oils and chemicals without compromising on performance.

– **Advantages:** High resistance to oils, chemicals, and weathering; moderate heat resistance.

– **Applications:** Ideal for trucks operating in oil-rich environments, such as construction and industrial settings.

Superior Vibration Absorption for Smooth Performance Our torque rubber cores are engineered to effectively absorb shocks and reduce vibrations, providing a smoother driving experience even in rugged conditions. This enhances driver comfort while protecting other vehicle components from wear.

Crafted from high-quality, durable rubber materials—such as natural rubber, neoprene, and polyurethane—our torque cores are built to withstand extreme temperatures, oils, and harsh environments, ensuring a long-lasting performance that saves on replacement costs.

Designed specifically for heavy-duty trucks, our torque cores offer exceptional load-bearing capabilities. This ensures that they perform reliably under the intense pressure of high loads, making them suitable for demanding applications like construction, mining, and long-haul transportation.

With customization options available, we offer torque rubber cores tailored to your exact specifications, including material, size, and design. This ensures compatibility with various truck models and optimizes performance for specific operating environments.

Or contact us to see our certificates

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

Please fill the from to contact us and we’ll get back to you right away!