Menu

Investing in high-quality bushings is an investment in the longevity and performance of your truck. Our bushings are designed to provide unmatched durability, vibration damping, and overall reliability. By choosing our bushings, you’re not just buying a product; you’re buying peace of mind. Whether you’re a long-haul trucker or a fleet manager, our bushings are the perfect solution to keep your trucks running smoothly and efficiently.

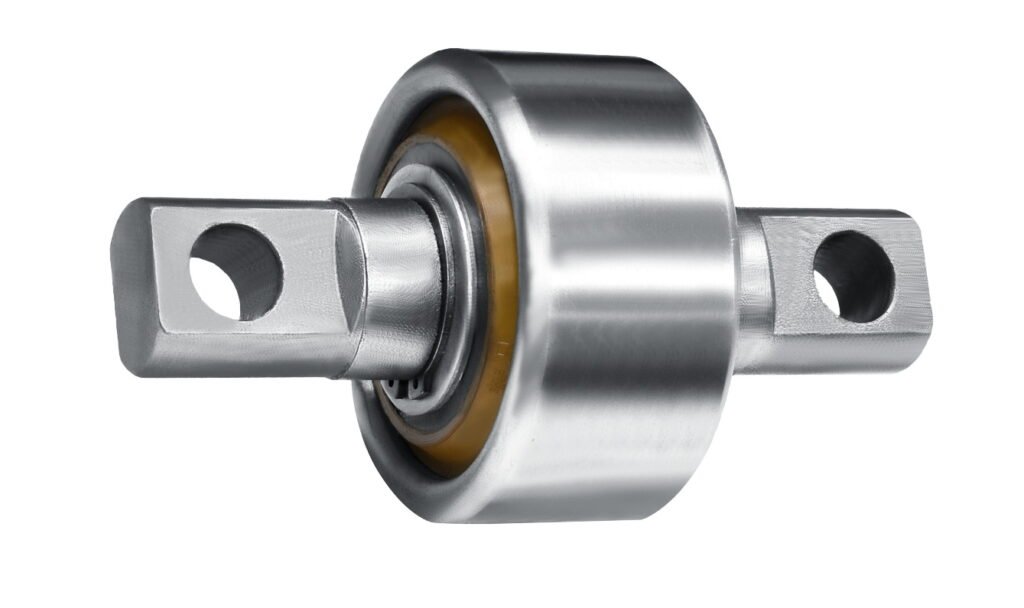

Special Structural Design Buffer Layer: Some new types of torsion rubber bushings have added a nylon buffer layer inside the rubber layer to reduce the

Proper alignment of the axles is crucial for the truck’s stability and handling. Torque rubber cores help maintain the correct alignment even under heavy loads

Engine mounting Having accumulated over 30 years of experience in the factory, we have thoroughly mastered the techniques requisite for fabricating premium – grade

Hino 700 Engine Mounting 12035-E0040/12035-E0031 Material: Top 100% nature rubber and Ingredients are from European. Temperature Resistance: Our Material supports as low temperature as minus

HINO Engine Mounting 12035-E0071/12035-3191 We independently manufacture rubber, employing imported raw rubber materials. Our dedicated rubber – mixing machinery guarantees the production of high

Engine mounting Material: Top 100% nature rubber and Ingredients are from European

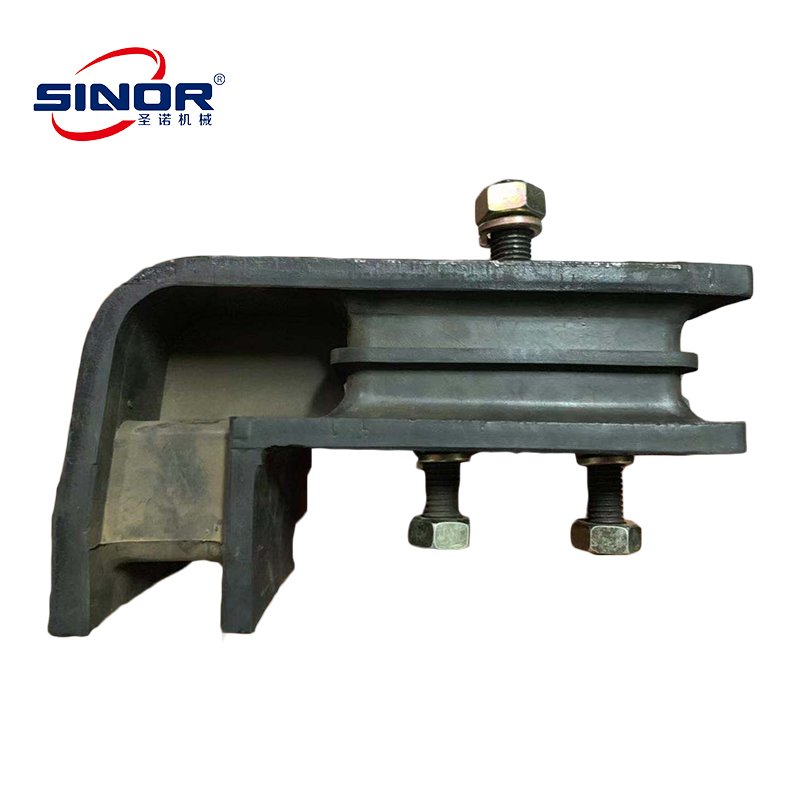

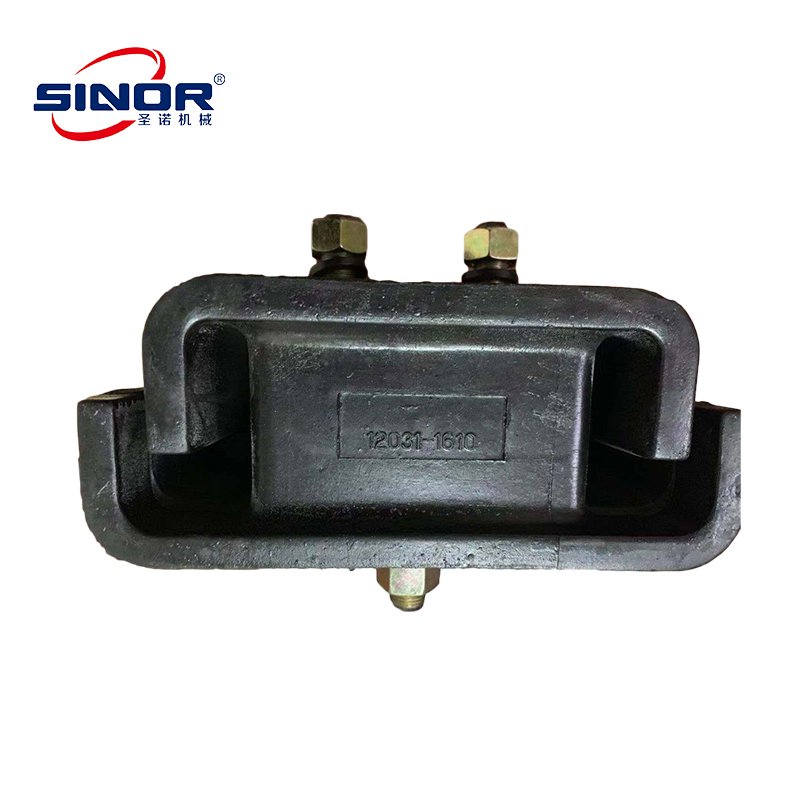

HINO Engine Mounting 12031-1310/12031-1330/12031-1460/12031-3400 Material: Top 100% nature rubber and Ingredients are from European.

Engine Mounting Impact Resistance: Our Rubber material can support at least 22mpa Impact without any damage, which can make sure the safety during long time

Engine Mounting Raw Material and Production We take pride in our self – sufficiency in rubber production of Engine mounting. By using imported raw rubber

HINO Truck Engine Mounting We are capable of designing and developing molds to produce customized rubber pads in strict accordance with specific technical requirements,

HINO Engine Mounting 12035-2881 Impact Resistance: Our Rubber material can support at least 22mpa Impact without any damage, which can make sure the safety during

HINO Engine Mounting OEM: 12031-1610 Keep Warranty: As long as 2years, rubber no Spoilage

QUANZHOU SINOR SUPPLY IN TORQUE ROD BUSH, V STAY, CONTROL BALL JOINT, AUTO BUSHING RUBBER BUSHING,CENTRAL BEARING SET, ENGINE MOUNTING, REPAIR KITS ETC. OURPRODUCTS ARE SUTTABLE FOR MERCEDES,VOLVO,SCANIA,MAN,HOWO,HYUNDAL,ISUZU,NISSAN,MITSUBISH,FAW SIE.DELONG,AUMEN DAFC AND OTHER BRANDS OF HEAVY TRUCKS.

Natural rubber is a widely used material in heavy-duty applications because of its excellent elasticity, flexibility, and resilience. Torque cores made from natural rubber are effective in absorbing vibrations and handling a wide range of temperatures, making them ideal for general applications where durability and flexibility are required.

Polyurethane is a highly durable and resilient material that offers excellent load-bearing capacity and impact resistance. PU torque cores are commonly used in extreme heavy-duty applications, as they provide long-lasting durability and support.

Neoprene rubber is valued for its resistance to oil, heat, and weathering, making it suitable for heavy-duty trucks that frequently encounter harsh environments. Torque cores made from neoprene can withstand higher temperatures and exposure to oils and chemicals without compromising on performance.

– **Advantages:** High resistance to oils, chemicals, and weathering; moderate heat resistance.

– **Applications:** Ideal for trucks operating in oil-rich environments, such as construction and industrial settings.

Superior Vibration Absorption for Smooth Performance Our torque rubber cores are engineered to effectively absorb shocks and reduce vibrations, providing a smoother driving experience even in rugged conditions. This enhances driver comfort while protecting other vehicle components from wear.

Crafted from high-quality, durable rubber materials—such as natural rubber, neoprene, and polyurethane—our torque cores are built to withstand extreme temperatures, oils, and harsh environments, ensuring a long-lasting performance that saves on replacement costs.

Designed specifically for heavy-duty trucks, our torque cores offer exceptional load-bearing capabilities. This ensures that they perform reliably under the intense pressure of high loads, making them suitable for demanding applications like construction, mining, and long-haul transportation.

With customization options available, we offer torque rubber cores tailored to your exact specifications, including material, size, and design. This ensures compatibility with various truck models and optimizes performance for specific operating environments.

Or contact us to see our certificates

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

Please fill the from to contact us and we’ll get back to you right away!