HINO Engine Mounting OEM: 12035-E0040/12035-E0031

HINO ENGINE MOUNTING Material: Top 100% nature rubber and Ingredients are from European.

HINO ENGINE MOUNTING Material: Top 100% nature rubber and Ingredients are from European.

HINO Engine Mounting OEM: 12302-56070L/12302-56070R Temperature Resistance: Our Material supports as low temperature as minus 30degree, as high as 90degree, totally compatible with Microwave and

HINO ENGINE MOUNTING Extensive Experience Our factory has a remarkable track record of over 30 years in the industry. This long – standing presence has

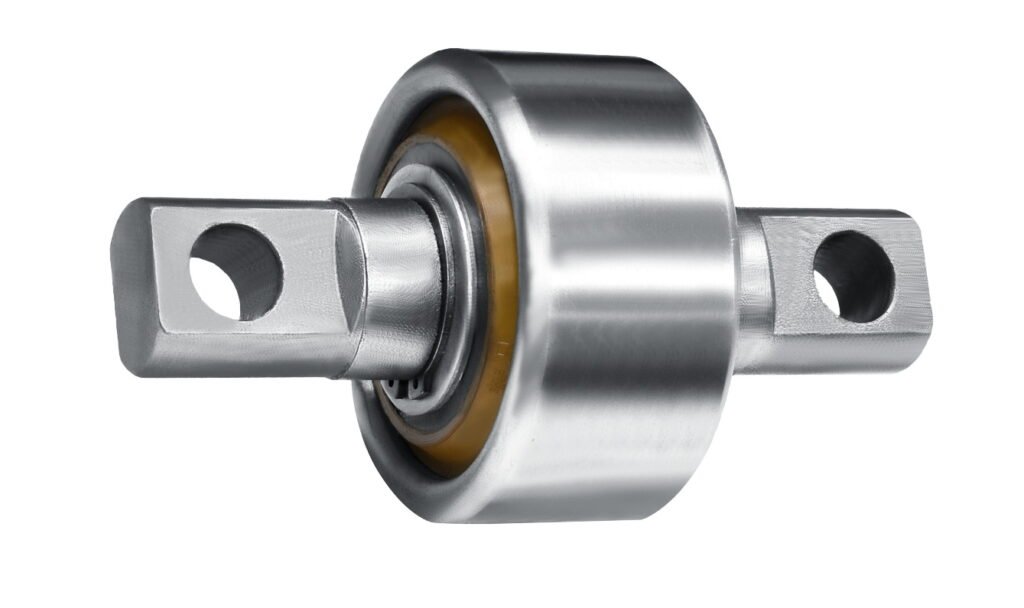

The torque rod bush is crafted through precision molding and high-grade rubber material, ensuring durability and superior torque resistance. Our advanced manufacturing process guarantees consistent

HINO Truck Engine Mounting Oem:12031-1610 Rubber We are capable of designing and developing molds to produce customized rubber pads in strict accordance with specific technical

High-quality products with competitive price

Our company adopts advanced manufacturing technology and strict quality control to ensure stable product quality.Through continuous technological innovation, we improve product performance and meet customers’ high-quality needs.We have mastered both the production and sales links, we can provide customers with more competitive prices. At the same time, we can flexibly adjust production and sales strategies according to market demand and customer feedback to further optimize costs and services.

Torque rubber cores, also known as torque rod bushings, are flexible components typically made of high-quality rubber or rubber-metal composites. They are mounted on torque

Basic Components: The center bearing set typically consists of an inner ring, outer ring, rolling elements (such as steel balls or rollers), and a cage.

Packaging & Shipping When it comes to packaging and shipping, we prioritize both safety and efficiency. Our packaging is designed to protect the bearings from

Certifications & Stability Our Center Bearing Set is backed by stringent certifications, guaranteeing its quality and reliability. These certifications ensure that our product meets the

Metal Components: The inner and outer rings, as well as the rolling elements, are usually made from durable metal materials such as steel. These materials

Vibration Damping Reduction of Driveline Vibrations: The center bearing set acts as a vibration damper, absorbing and reducing the vibrations generated by the driveshaft. This

High-toughness rubber with rigorous processing resists cracking, aging and wear (double that of ordinary mats). Sealed surface enables easy cleaning, ideal for oil-prone environments.

Fits Isuzu NPR, DMAX, FTR models perfectly. Flexible for multi-scene use, cuttable to size, non-slip, and installable by one person without tools.

Absorbs drivetrain vibration and reduces noise, protects metal components from impact. Ensures smooth torque transmission for reliable vehicle performance.

High-toughness rubber with precision processing resists cracking, aging and wear. Excellent elasticity ensures stable torque transfer even in harsh working conditions.

QUANZHOU SINOR SUPPLY IN TORQUE ROD BUSH, V STAY, CONTROL BALL JOINT, AUTO BUSHING RUBBER BUSHING,CENTRAL BEARING SET, ENGINE MOUNTING, REPAIR KITS ETC. OURPRODUCTS ARE SUTTABLE FOR MERCEDES,VOLVO,SCANIA,MAN,HOWO,HYUNDAL,ISUZU,NISSAN,MITSUBISH,FAW SIE.DELONG,AUMEN DAFC AND OTHER BRANDS OF HEAVY TRUCKS.

Natural rubber is a widely used material in heavy-duty applications because of its excellent elasticity, flexibility, and resilience. Torque cores made from natural rubber are effective in absorbing vibrations and handling a wide range of temperatures, making them ideal for general applications where durability and flexibility are required.

Polyurethane is a highly durable and resilient material that offers excellent load-bearing capacity and impact resistance. PU torque cores are commonly used in extreme heavy-duty applications, as they provide long-lasting durability and support.

Neoprene rubber is valued for its resistance to oil, heat, and weathering, making it suitable for heavy-duty trucks that frequently encounter harsh environments. Torque cores made from neoprene can withstand higher temperatures and exposure to oils and chemicals without compromising on performance.

– **Advantages:** High resistance to oils, chemicals, and weathering; moderate heat resistance.

– **Applications:** Ideal for trucks operating in oil-rich environments, such as construction and industrial settings.

Superior Vibration Absorption for Smooth Performance Our torque rubber cores are engineered to effectively absorb shocks and reduce vibrations, providing a smoother driving experience even in rugged conditions. This enhances driver comfort while protecting other vehicle components from wear.

Crafted from high-quality, durable rubber materials—such as natural rubber, neoprene, and polyurethane—our torque cores are built to withstand extreme temperatures, oils, and harsh environments, ensuring a long-lasting performance that saves on replacement costs.

Designed specifically for heavy-duty trucks, our torque cores offer exceptional load-bearing capabilities. This ensures that they perform reliably under the intense pressure of high loads, making them suitable for demanding applications like construction, mining, and long-haul transportation.

With customization options available, we offer torque rubber cores tailored to your exact specifications, including material, size, and design. This ensures compatibility with various truck models and optimizes performance for specific operating environments.

Or contact us to see our certificates

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

Please fill the from to contact us and we’ll get back to you right away!